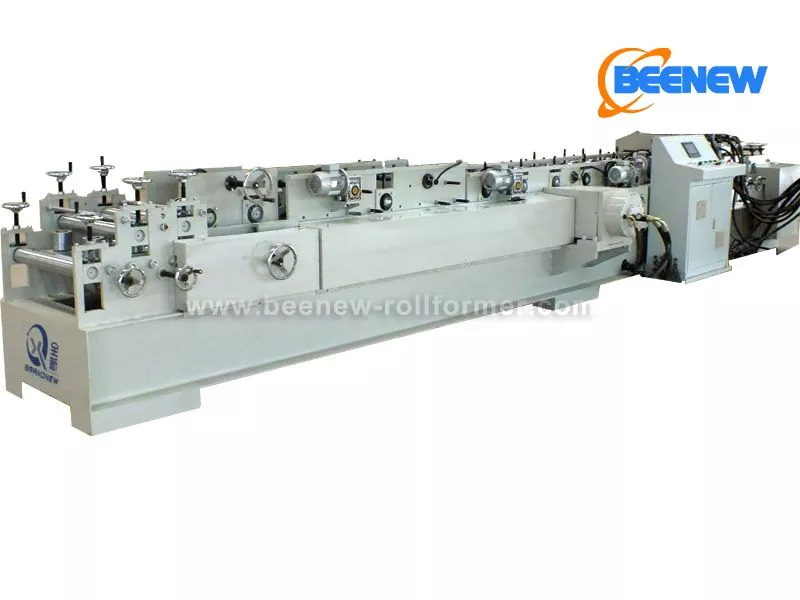

Cパーリンロール形成マシン

お問い合わせを送信

Cパーリンロールフォーミングマシンは、多様な建設ニーズを満たすように設計されています。プロジェクトに完全に合うように、C、Z、または組み合わせのCZスタイルから選択してください。最適なパフォーマンスのために、標準モーターバージョンまたは高度なサーボモーターバージョンを選択します。当社のマシンは、さまざまな材料の厚さに対応します。CZ50-200のOPTまたは標準材料用のCZ80-300、または重いアプリケーションのCZ100-350またはCZ140-400にアップグレードします。コントロールモードに関連すると、コンピューター制御のタイプとデジタルディスプレイ命令タイプがあります。あなたの選択を特定の要件に合わせて調整し、パーリン生産における比類のない効率と品質を体験してください。カスタマイズ可能なソリューションで今日のプロジェクトを高めてください!

パーリンロール形成マシンパラメーター

以下は、サーボモーターを備えたveew c50-200パーリンローリングマシンのパラメーターです。

|

アイテム |

パラメーター |

|

下幅 |

C50-200mm |

|

パーリンの高さ |

C21-58mm |

|

材料の厚さ |

Q235(1.0-2.0mm) |

|

給餌幅 |

96-350mm |

|

トランスミッションモーター |

11kwサーボモーター |

|

パンチ&カットモーター |

4.0kw |

|

変更モードを入力します |

デジタルディスプレイ |

|

シャフトの直径 |

フォーミング:芽/45mmレベリング:アカデ |

|

ローラー素材 |

GCR15ベアリングスチール /CR12ダイスチール |

|

速度制御モード |

サーボドライブの速度制御 |

|

ステーションを形成します |

13ステーション |

|

切断/パンチングモード |

事前カットとパンチング |

|

長さの精度を切断します |

±2mm |

ロールフォーミングマシン機能

コンピューター制御タイプの代わりに、このPurlinマシンは半自動タイプです。効率と柔軟性のために設計されています。以前は、スリーブの交換はほぼ100分かかり、フォーミング仕様が断続的な段階に制限されていました。現在、革新的なデジタルディスプレイ変換により、このプロセスはわずか10分に合理化されており、生産性が大幅に向上しています。この前者を作ることは、予算の制約を備えたスタートアップに最適です。費用対効果の高いソリューションです。

パーリンマシンの詳細

veereew corlinマシンの機械フレームと壁パネルは、細心の溶接プロセスを経て、それに続いて美学を促進するだけでなく、長期にわたる耐食性を提供する高品質のスプレー塗装仕上げが続きます。

各コンポーネントは、オーブンのベーキング、クロムメッキ、亜鉛めっき、黒ずみなどの高度な技術で処理され、すべてのピースが輸出基準を満たしていることを確認します。

Purlin Forming Machineのローラーは、GCR15ベアリングスチールで作られたフラットホイールを備えており、その硬度と耐摩耗性で有名です。傾斜したホイールは、CR12ツールスチールから作られており、並外れた強度と信頼性を提供します。

プルリンローリングマシンの切断ブレードは、高品質のツールスチールから製造され、厳密な熱処理を受けます。このプロセスは、ブレードの耐久性とシャープネスを強化し、清潔で正確なカットを可能にします。

日本語

日本語 English

English lugha ya Kiswahili

lugha ya Kiswahili  Монгол хэл

Монгол хэл  Español

Español  Português

Português  русский

русский  Français

Français  Italiano

Italiano  한국어

한국어  Malay

Malay  हिन्दी

हिन्दी  Türkçe

Türkçe  العربية

العربية  Indonesia

Indonesia  تمل

تمل  український

український  فارسی

فارسی  Latine

Latine  Azərbaycan

Azərbaycan